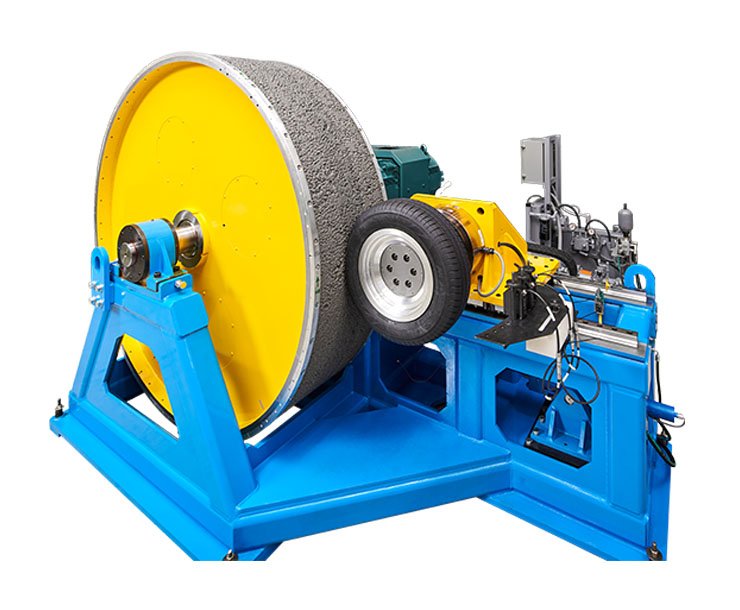

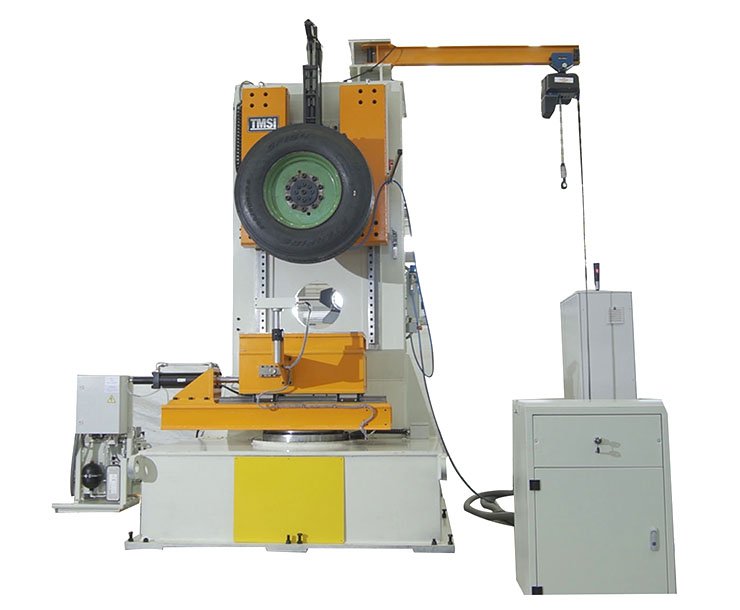

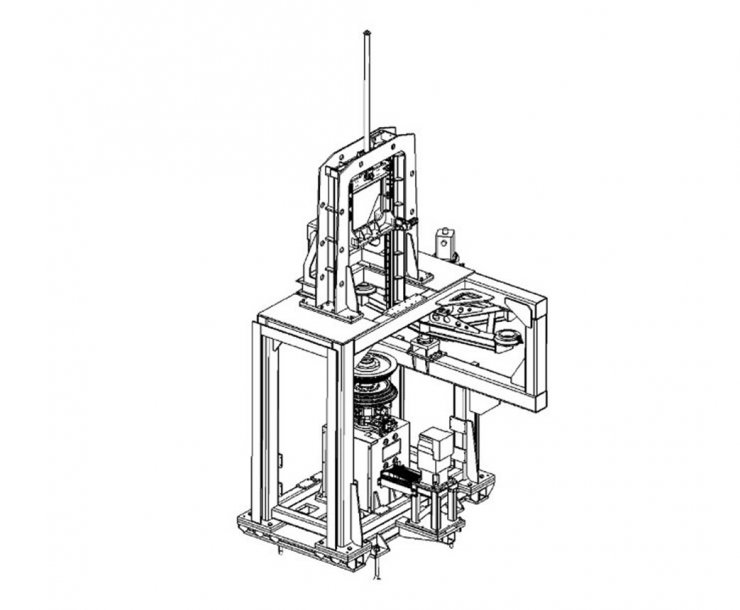

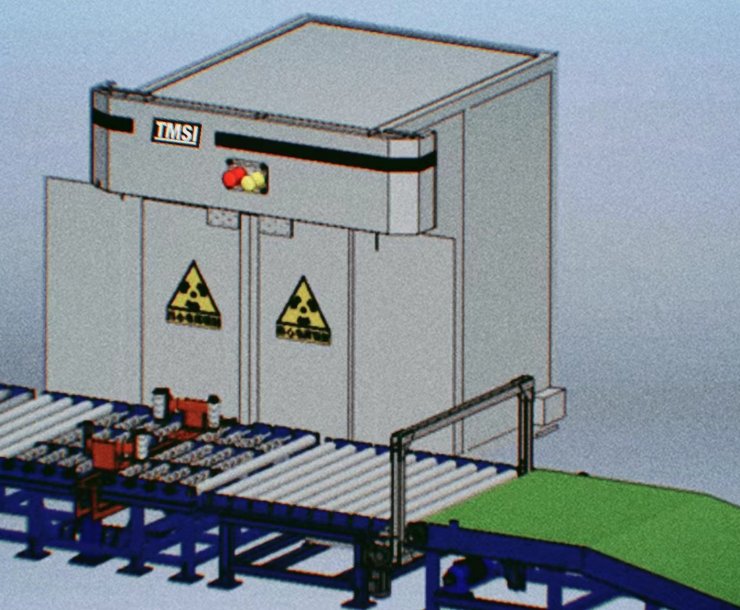

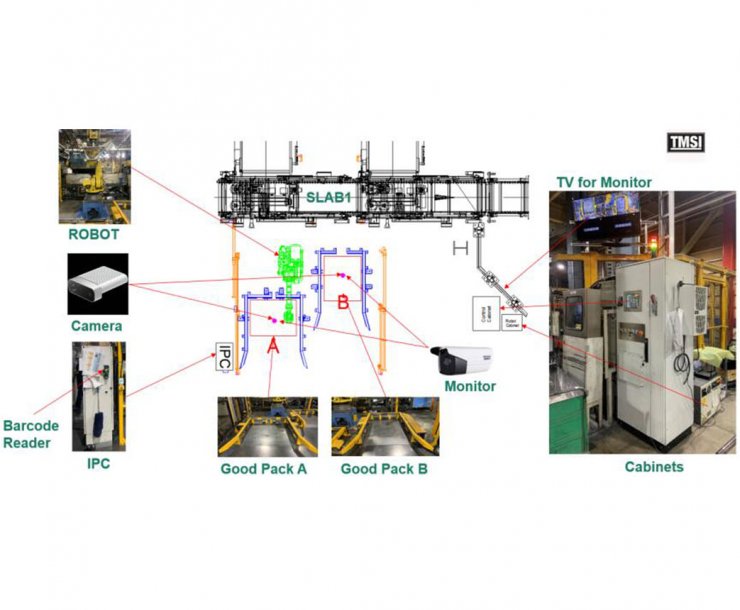

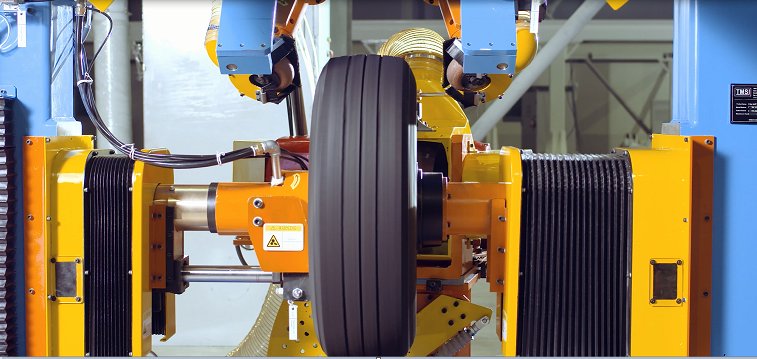

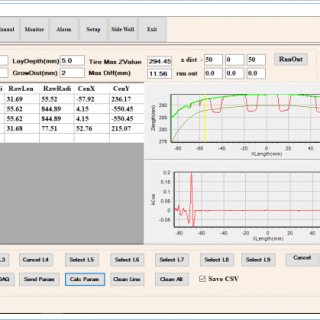

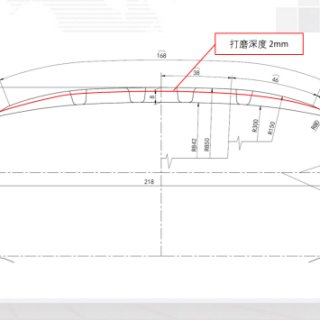

TMSI has developed the tire buffing systems TM-PCR400 and TM-TBR225 for Passenger and Light Truck tires and for Truck tires. Our tire buffing machines, of the TM series, provide a solution for creating a "tire in service" with a specific degree of wear for performance testing, it helps to improve the tire uniformity and dynamic balance. The TM-PCR400 and TM-TBR225 utilize a tread profile measurement system, which measures the tire profile before buffing, provides the data for buffing controls to specific curve during the buffing process, and measures the tire profile after buffing.

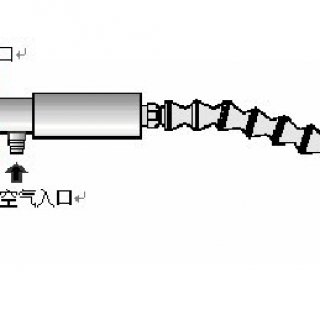

The buffing system is designed within an enclosure to prevent contamination of the plant and lab areas, increases operator safety, and reduces noise during operation( Noise level below 80dB measured outside the enclosure). This also allows for the integration of an air Cooling System. With this cooling, the TM-PCR400 and TM-TBR225 reduce the tire temperature during the grinding process to improve the accuracy of the grinding, as well as reduce the cycle time to grind by up to 50%.

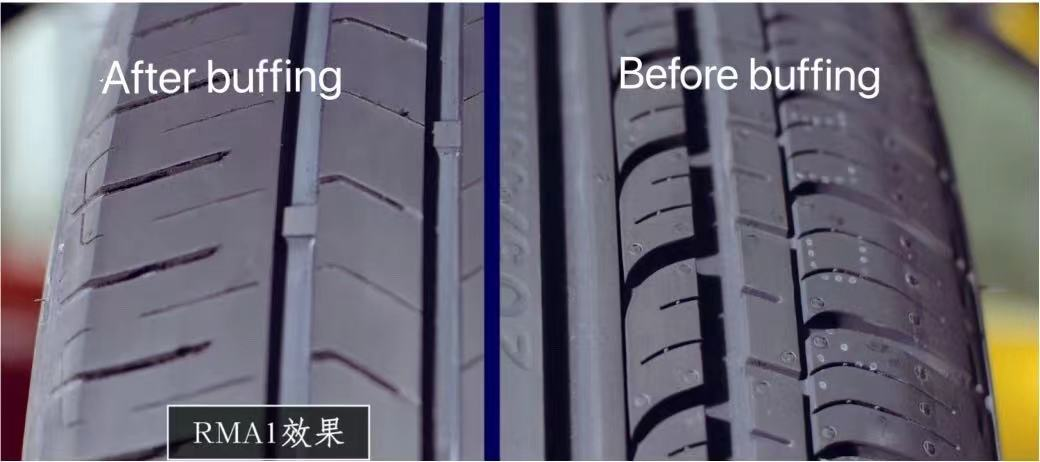

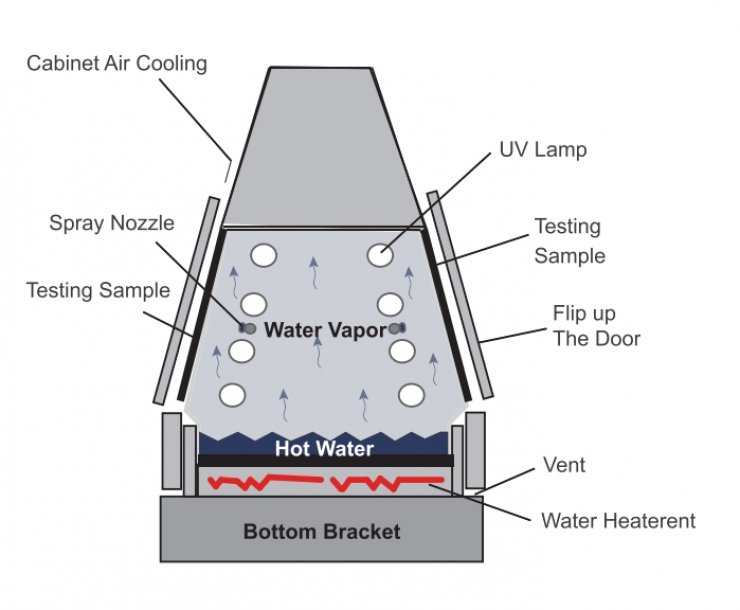

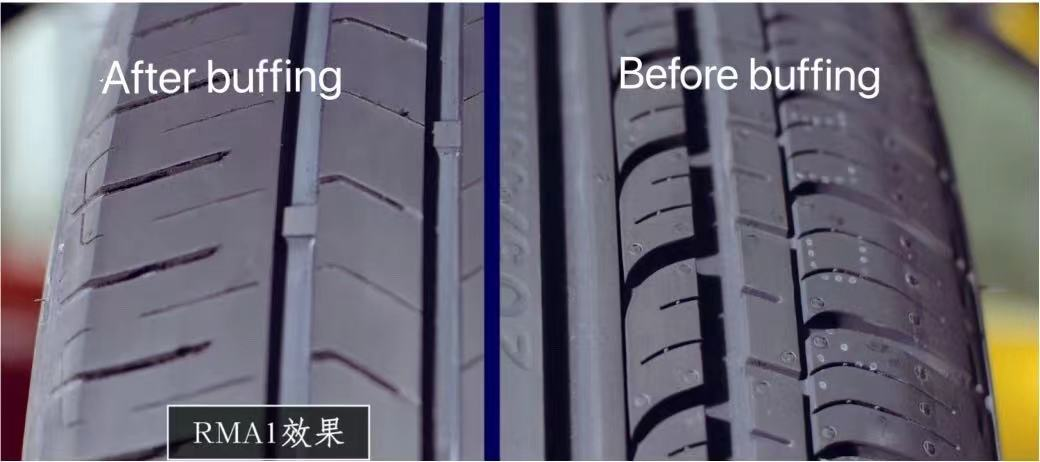

Contrast of the tire tread buffing effect