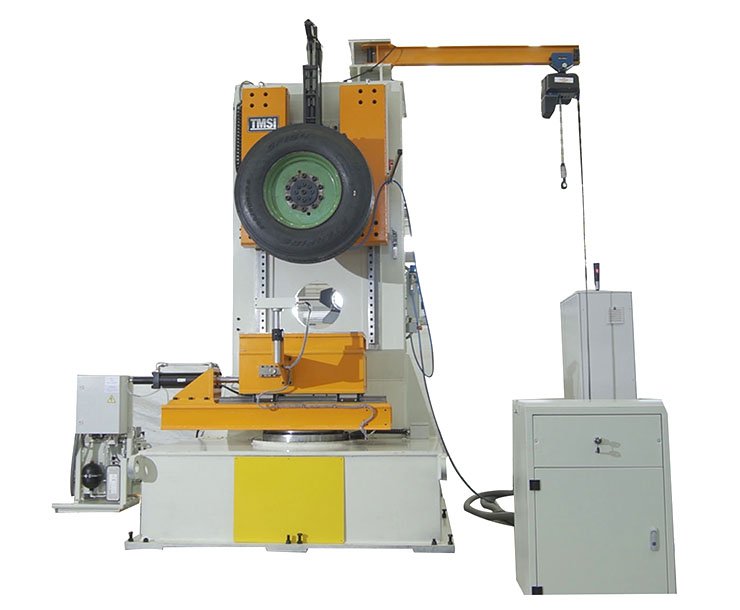

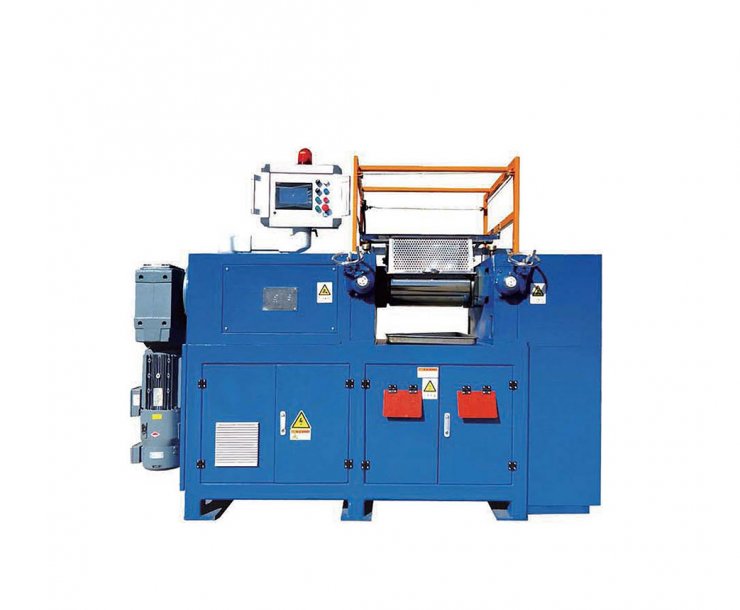

The machine is suitable for vulcanizing tire tread products. The structure is jaw type and the pressing form is down (up) pressing type. The tread vulcanizing machine provides strong and stable pressure, and comprehensive electrification control, which ensures the reliability and consistency of the whole vulcanizing process. The tread products produced are of excellent performance and stable quality. The machine is with high quality carbon knotted steel body, stable structure, corrosion resistance, long service life of the whole machine, easy to maintain.

The machine has the following features:

1、The tread vulcanizing machine is equipped with automatic pushing and pulling die, and the unit surface pressure is large, the produced tread is wear-resistant.

2、The machine adopts PLC electric appliances to automatically control the vulcanization time, mold opening and closing, pushing and pulling, etc.

3、The machine adopts high and low pressure vane pump, with low operating noise and stable performance.