- Home

-

Products

-

Testing

- Motorcycle Tire Load Deflection Test Machine

- Tire Buffing Machine

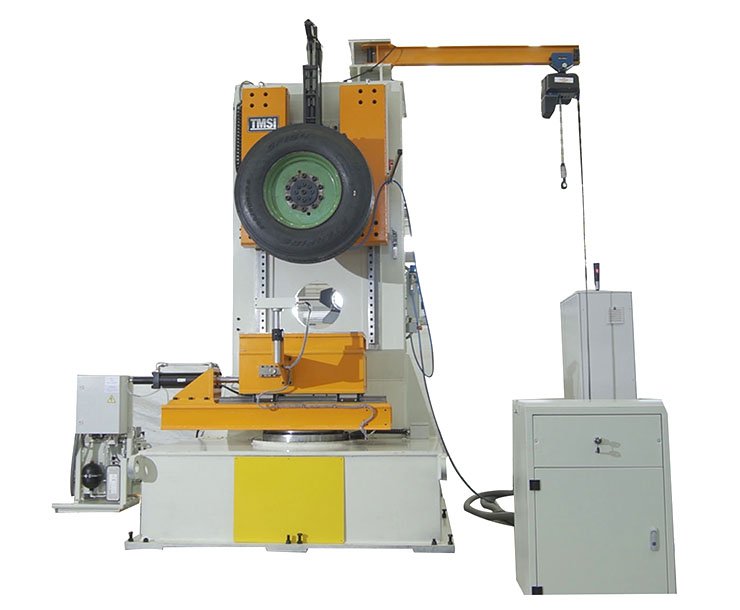

- Tire Force and Moment Test Machine

- Tire High Speed Uniformity Test Machine

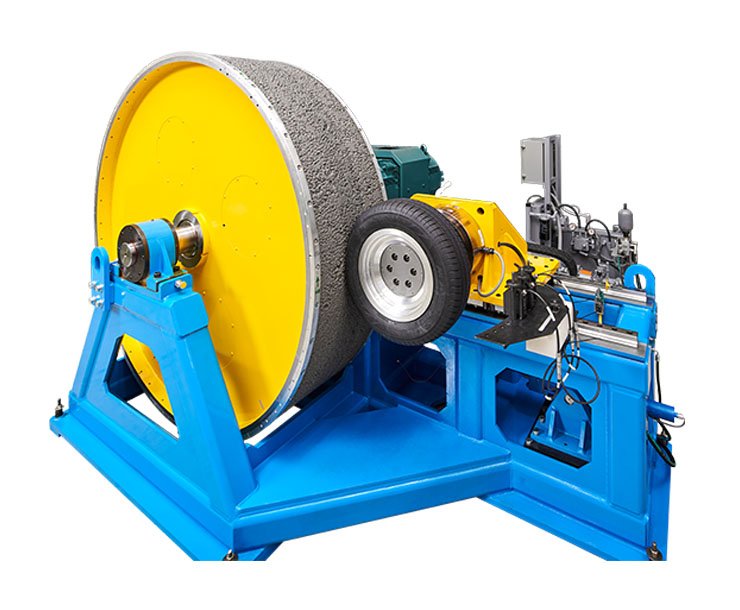

- Tire Rolling Resistance Test Machine

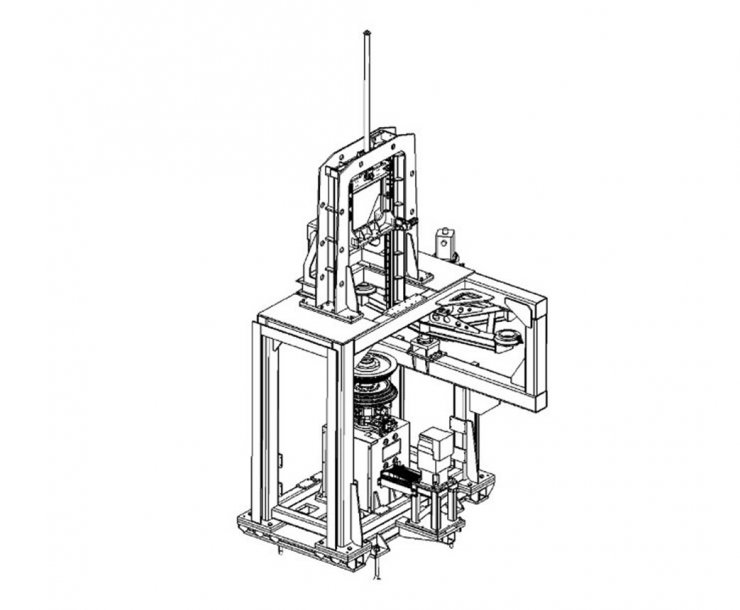

- Tire Load Deflection Test Machine

- Tire Endurance Test Machine

- Noise, Vibration, and Harshness Machine

- Seat Testing System

- Seatbelt Testing System

- Tire Dynamic Imbalance and Geometry Test Machine

- Vision

- Machinery

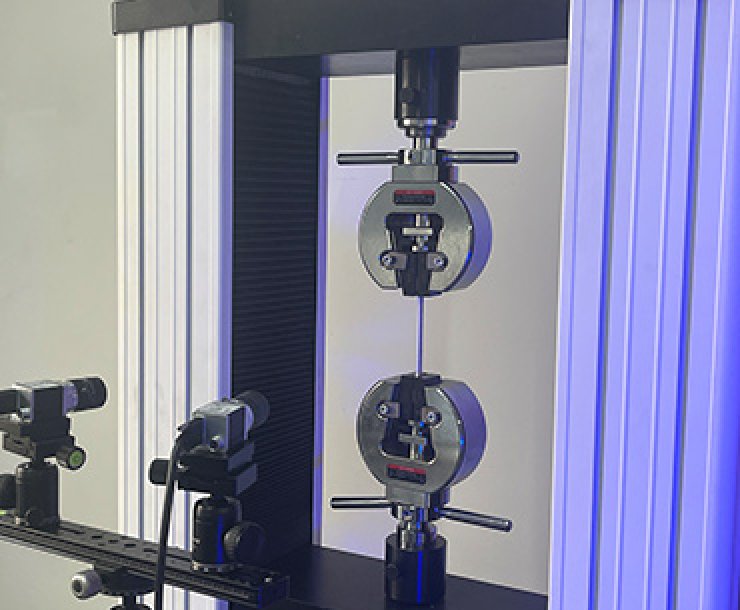

- Tensile Tester

- Chambers

- Robot

-

Testing

-

Testing

- Motorcycle Tire Load Deflection Test Machine

- Tire Buffing Machine

- Tire Force and Moment Test Machine

- Tire High Speed Uniformity Test Machine

- Tire Rolling Resistance Test Machine

- Tire Load Deflection Test Machine

- Tire Endurance Test Machine

- Noise, Vibration, and Harshness Machine

- Seat Testing System

- Seatbelt Testing System

- Tire Dynamic Imbalance and Geometry Test Machine

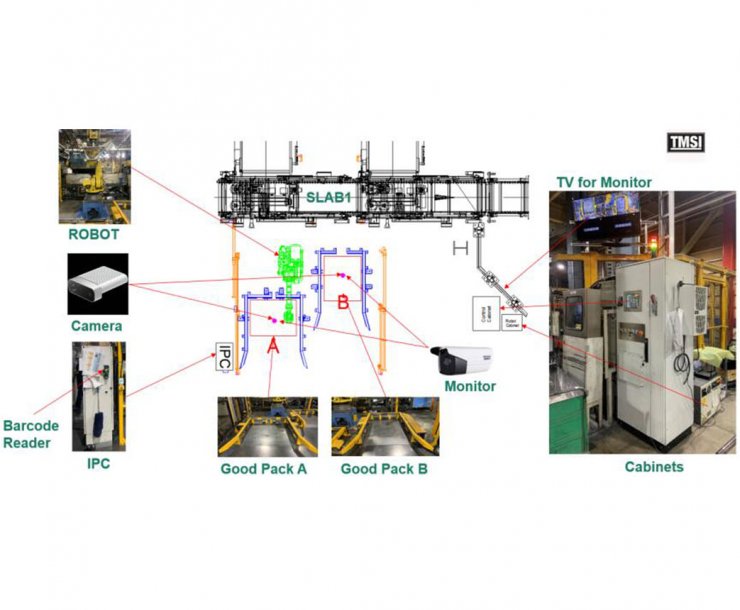

- Vision

- Machinery

- Tensile Tester

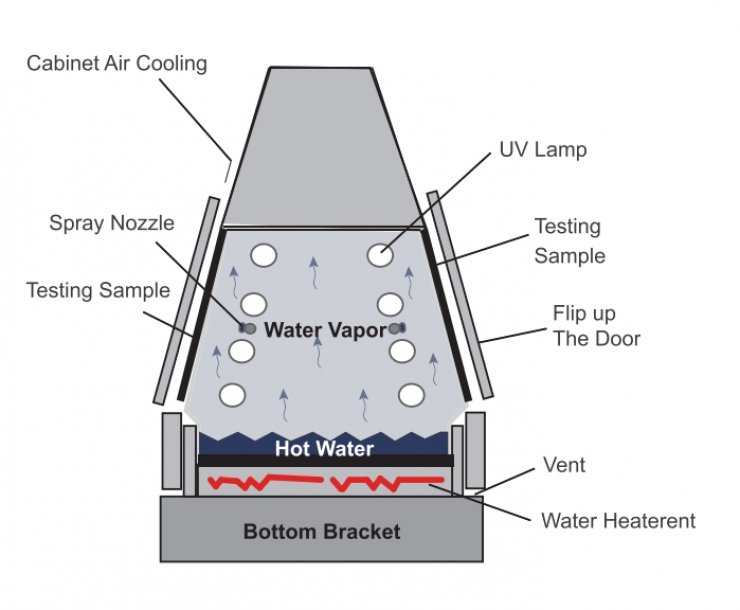

- Chambers

- Robot

- Research

- Service

- News&Events

- About

- Contact