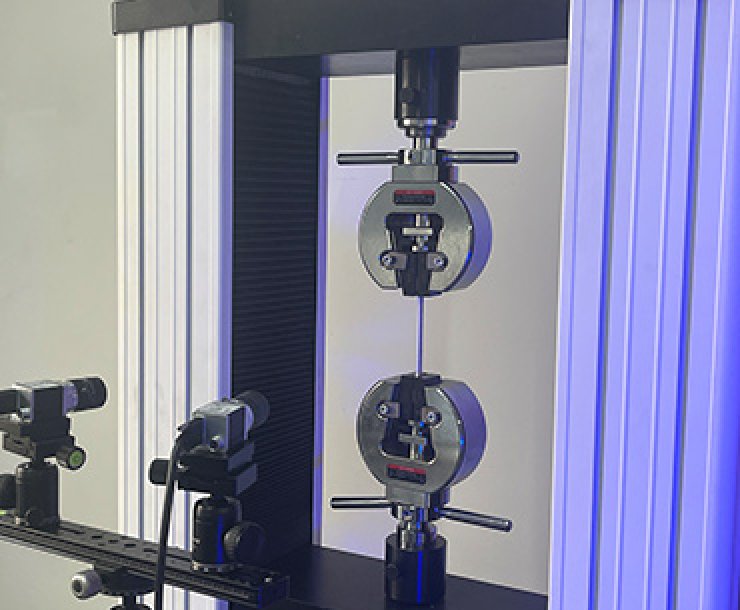

TMSl 3D suited for complex analysis in3D based on non-contact measurementusing digital cameras and Full-fieldstrain Measurement System. Bothstatic and dynamic events can be evaluated.

The system offers a full-field analysis of deformation and displacement including velocity and acceleration.

Measurement methodology allows for the measurement of high strain rates, high-speed testing, vibration measurement, FEA analysis, crack propagation, dynamic testing, and quality control. Three main measurement methodologies are the followed.

(1) MATERIAL TESTING: 2D/3D Video extensometer (VEX)、Extension and contraction measurement (longitudinal, transversal)、Chain probe tool for rebar measurement、Neck gauge detection tool、Virtual strain gauge tool、Natural pattern measurement、High-temperature measurement、Crack length propagation measurement、Cycle counting in fatigue tests

(2) COMPONENT TESTING: Static, quasistatic, dynamic measurement、Full-field strain distribution measurement、Integrated high-speed camera、Point and area measurement of motion、Sampling synchronisation with the dynamic and periodic events、Kinematic analysis、Component measurement under operational or laboratory conditions、API for customised I/O communication and control、Pressure chamber measurement、Thermomechanical measurement、Thermal camera integration、FLC (forming limit curve) analysis and evaluation、Bulge test analysis (sheet metals, rubber).

(3) VIBRATION ANALYSIS:Video stroboscopy functionality、Modal vibration testing、Operational deflection shapes measurement、Measurement of displacement, velocity, acceleration, and strain、FFT, Campbell diagram, power spectral density, crest factor determination、Vibrographic sync-box with shaker control、Integrated high-speed camera I/O.